Happy Embroidery Month!

Here at Vantage, we jump at every opportunity to share our love for all things related to decorated apparel. As leaders in the promotional apparel industry, it’s only natural that we celebrate the design technique that started it all, embroidery. With more than 500,000 different embroidered logos under our belt, 1200 embroidery heads and the industry’s most experienced digitizers and operators, no other company does it better than Vantage.

We recently accepted our 22nd PPAI Gold Pyramid Award for Supplier Decorating in the category of Embroidery, recognizing us for our outstanding craftsmanship, creativity and service to distributors. In celebration of Embroidery month, we sat down with Dave Buzinkai, our in-house expert digitizer behind the winning design to talk about the intricate techniques he used to create the stunning full-back logo.

Q: How did you get started in design and how long have you been with Vantage?

Dave: I started working for Vantage in May of 1994, so just shy of 24 years. I actually didn’t start as a digitizer. We got so busy at times, that I helped out where ever it was needed and basically taught myself how to digitize. I would create the file and go watch it run on the embroidery machine.

Q: The full-back seascape logo is so intricate; take me through the design process from start to finish?

Dave: The process started with the customer’s art. In this case, we received a rather low resolution jpeg file. Since we need to be zoomed in very close to what we are digitizing, adjustments were necessary to keep the art from becoming pixilated. The artwork was then used as a “backdrop” and I digitized directly over it. I choose the stitch type, direction, color, technique, and sequence while doing this. When the initial file was completed, we ran a test swatch on the actual fabric to make any changes before doing the final sew out on the garments.

Q: So you’ve been with Vantage for close to 25 years, I’m sure you’ve digitized thousands of designs. Do you have a favorite design?

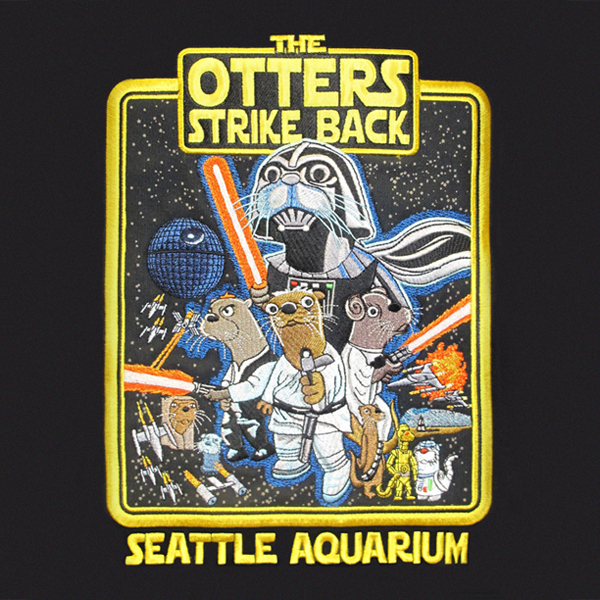

Dave: I don’t know if I really have a favorite design. If I had to choose one, I think it would be the “Amazing Cow Heroes”. There is just so much going on in that design and it came out awesome. The “Seattle Aquarium (The Otters Strike Back)” was probably the most fun to design. Every really creative design is a huge challenge, but one of the hardest ones I ever did was the “Uncle Sam”. The entire design is blended embroidery and it was very difficult achieving all the depth in the face and hand.

Q: The design featured exquisite details that truly captured the beauty of the sea. Tell me a little about the techniques and stitches used to achieve some of the details.

Dave: I found areas that I wanted to accentuate, like the water.

I added liquid and Florentine effects, which make the stitches curve. It gave this design a lot of depth and created the movement of the water. We took it a step further and added metallic threads and blended them together. I used blended fills and motif stitches to create a lot of the details.

Q: As one of the oldest fabric decorating techniques, what makes embroidery continue to be preferred by brands today?

Dave: Embroidery is a classy way of putting a design on a garment. The thread has depth and texture and looks three dimensional. It can also be done on uneven surfaces. Many garments that have a rougher texture can’t be screen printed. Embroidery doesn’t wear off and can be laundered without special considerations other than the garment.

Q: How often are you given creative freedom over a customer’s project? Do you have any examples?

Dave: A lot of our designs are established logos and we can’t change them much. But, whenever we can, we like to incorporate any special techniques like blending, textured fills, etc. It’s usually a project like this where the customer leaves us a lot of creative freedom. They really want to see what we can do with their design.

Q: Do you have any tips for someone looking to use embroidery for their branded apparel?

Dave: It’s always a good idea to know what type of garment you want to sew your design on before it’s digitized. This way, the optimal stitch densities, types, and techniques are used. Using too many stitches is just as bad (sometimes worse) than not enough stitches. Take the lightweight performance fabrics for example; using too many stitches can easily create holes in the garments.